Originally posted 2022-04-02

For petanque players with back issues, a magnetic boule lifter can be a life-saver. You can buy one on the web, or you can make your own. This design for a home-made lifter is as good as, or better than, many of the ones you see for sale on the web.

MATERIALS

All of the materials should be available at your local hardware store. When I did this project in April 2022 in Tucson, Arizona, the total cost of materials was between $15 and $20. You will need—

- Silicon glue. About $8 at my local hardware store.

- One eye bolt with a diameter of 1/4″ and a length of about 2.5 inches. Enough nuts (probably around 6 or 7) to fill all the threads of the eye bolt. Two small washers with a 1/4″ hole. And a plastic bottle cap from a bottle of soda.

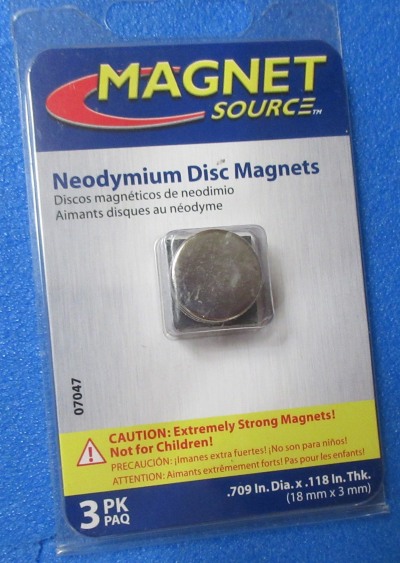

- One nickle-sized neodymium disc magnet (18mm in diameter and 3mm thick). A 3-pack cost me $6.60 at my local hardware store. These magnets are surprisingly strong— just one will be enough to pick up a petanque boule.

ASSEMBLING THE LIFTER

Drill a 1/4″ hole in the center of the bottle cap, so that it can be threaded onto the eye bolt.

Tightly screw enough nuts onto the bolt almost to fill its entire length.

Add one washer, then the bottle cap, then the other washer.

Finally, screw a nut tightly on to the end of the eye bolt so that it holds everything together.

Note that the end of the bolt doesn’t protrude out past the nut.

At this point you can place the magnet on the nut and see where it will be located when the project is complete.

Note that the magnet is positioned slightly below the edges of the bottle cap. That’s good. The magnet will be well protected.

Squirt a thin layer of silicon glue onto the nut.

Fill the area around the nut with more silicon glue.

Position the magnet on top of the nut and push it down firmly, so that it is glued to the nut.

The final step is to fill the area around the magnet with more silicon glue, right up to the edge of the bottle cap. The goal here is to create a rubbery silicon buffer around the magnet. The silicon buffer will support and protect the edges of the magnet, and the edges of the bottle cap will protect the silicon buffer.

Use something (like a knife) with a flat edge to scrape across the face of the magnet to give a smooth, flat surface to the silicon. Then if there is any glue on the face of the magnet, wipe it off with a Q-tip or paper towel so that the face of the magnet is clean.

Set the lifter aside to give the silicon glue time to cure. Since we’ve slathered on quite a lot of glue (rather than using it as a thin layer of adhesive), allow plenty of time for it to cure— I’d recommend three or four days. The silicon may pull away from the magnet as it cures, leaving a bit of a ragged-edged gap around the magnet. (See the photo, below.) If that happens, after the silicon has cured normally, apply a second small dollop of silicon to fill in the gap around the magnet. That second dollop of silicon will provide additional support for the edge of the magnet, and it will make the whole thing look nicer. (See the photo at the bottom of this page.)

Attaching a cord

When you attach a cord and a ring, your lifter will be ready to use. Note that I say “cord”, not “string”. Strings get tangled easily because they are thin and flexible. Something thicker and stiffer— a cord— won’t tangle so easily. For another boule lifter I used a light cotton cord (see picture below). In this project I used a heavy boot lace.

Select an iron or steel ring that can be grabbed by the magnet. (That way you can wear the lifter like a necklace when you’re not using it.) A split metal key ring works well enough, but I prefer a nice “welded ring” (like the one in this picture) which I got at my local hardware store for $1.60.

In the photo, the black whipping is done using 1.18mm micro cord from Atwood Rope. I learned how to do whipping (which is really quite easy) from Youtube videos like this one.

Using the boule lifter

After the silicon has completely set and you’ve attached the cord, the boule lifter will be ready for use. As of October 2023 I’ve been using the boule lifter shown in the photo at the top of this page for over a year. The construction seems to be quite strong enough— it has held up well and continues to function as well as the day it was made. Since then, I’ve made several similar ones for friends. Here’s a photo of my most recent one. Here, again, the cord I used was a heavy boot lace.